Automatic metal chips crushing compressor

The automation equipment is independently developed and designed to solve the metal cutting waste chips produced by CNC lathes, milling machines, machining centers, etc. in the process of processing parts manufacturing.

Add Your Heading Text Here

Equipped with a crushing blade box

- Equipped with opposite shear crushing blades.

- Suitable for metal cutting chips of different materials such as stainless steel, iron, aluminum, copper, etc.

Hydraulic power drive

- Equipped with small hydraulic motors, achieving equipment miniaturization and lightweight.

- Shorten crushing and compression time, improve overall equipment effectiveness.

Easy to use with touchscreen

- Visualized operation with touch screen.

- Stable control with PLC.

Low noise, energy-saving and environmentally friendly

- High performance, low noise.

- Recycling and reuse of cutting oil.

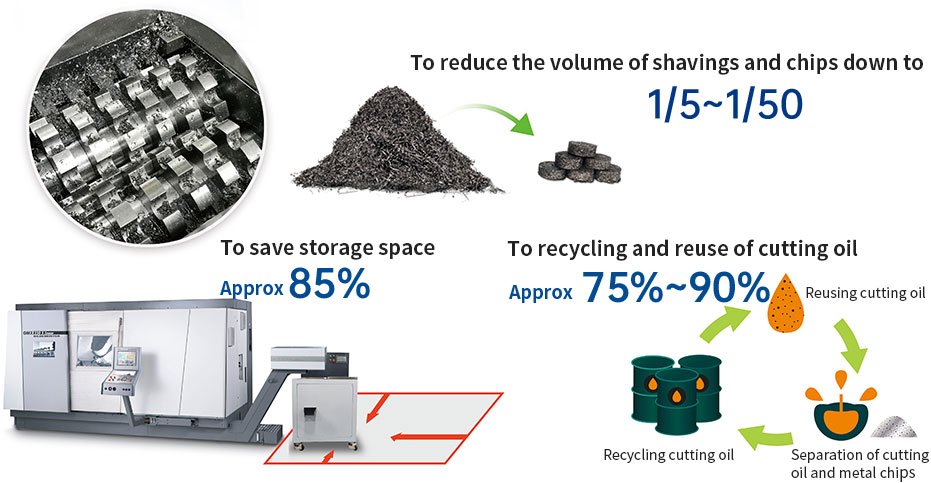

Targeted Effectiveness

To save storage space

Approx 85%

To save handling time

Approx 85%

To recycling and reuse of cutting oil

Approx 75%~90%

To reduce safety hazards by improving 5S production site environment Compressed and formed metal chips block could be sold for added value

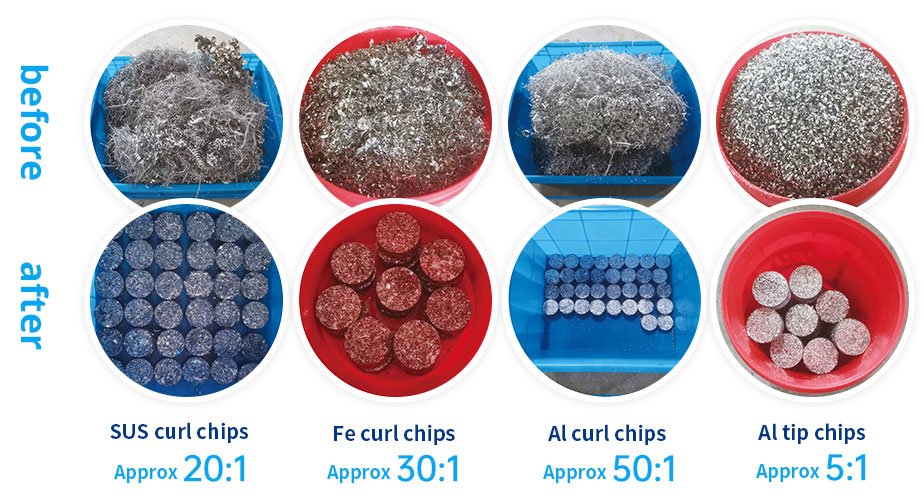

Different materials before and after compression

Main Specifications

| Product Name | Automatic metal chips crushing compressor |

| Model | WL-CCM-V100 |

| Chip Types Suitable for Processing | Suitable for metal cutting and shaving chips of different materials such as Stainless steel, iron, aluminum, copper, etc. |

| Block Dimension | Φ70mm |

| Power Supply | 380VAC / 50Hz / 3P+N+PE |

| Motor Capacity | 4.2KW |

| Rated current | 16A |

| Tank Capacity | 40L |

| Compressing Pressure | 18-20MPa |

| Control Panel | Touch Screen |

| Operating Time | approx 40S |

| Dimension | 850*720*1370mm |

| Approx. Mass | 520Kg |

This product can also be customized according to the actual needs of customers.