CNC Turning Service

Our CNC turning process produces custom prototypes and end-use production parts in as fast as 1 day. We use a CNC lathe with live tooling so features like axial and radial holes, flats, grooves, and slots can be machined.

CNC turning is often used for:

- functional prototypes and end-use parts

- parts with cylindrical features

- parts with axial and radial holes, flats, grooves, and slots

What is CNC Turning?

CNC turning is a subtractive manufacturing process that rotates a metal rod while a cutting tool is held against the stock to remove material and create final parts. Our CNC lathes are also equipped with live tooling that can machine flat features and holes into the workpiece. Outside diameter (OD) and inside diameter (ID) threading is also available.

Turned parts can then be left as-machined, with visible tool marks, or bead blasted. When the run is complete, parts are inspected, boxed and shipped shortly thereafter.

Our CNC Turning Capabilities

If you are looking for professional OEM/ODM CNC turning services or want to receive a high-quality CNC Turned part from a reputable and reliable supplier?

10+ Years Hakka Machinery had provided excellent quality CNC turned parts manufacturing for the United States and Europe customers on-demand, featuring precision machined parts, lathe parts. Our precision CNC Turning Parts applications exist in a variety of industries including automobile, electronics, medical and more. We mainly serve customers from the United States, Europe, the Middle East, and more countries & regions.

Not only can provide high-quality parts machining, but Hakka Machinery can also finish excellent surface finish, especially in anodic oxidation, polishing, copper plating, etc. We have been equipped with a high-precision tester, which can ensure the accuracy of the standard of the parts.

What Materials can be CNC Turned?

We work with a wide range of plastic and metal alloy materials, including magnesium, mild and stainless steel, aluminum, brass, and titanium, as well as rigid engineering-grade plastic resins. These materials are part of our standard inventory and can be sourced immediately from reliable, thoroughly vetted, and approved vendors. Additionally, we can provide specialty materials such as super-hard alloys—simply consult with our engineers to learn how we can meet your needs.

Most importantly, to ensure your CNC machined parts meet all regulatory requirements, we have an incoming materials inspection lab equipped with sophisticated analytic testing instruments, including Raman spectroscopy, to confirm the exact chemical and physical properties of all raw materials.

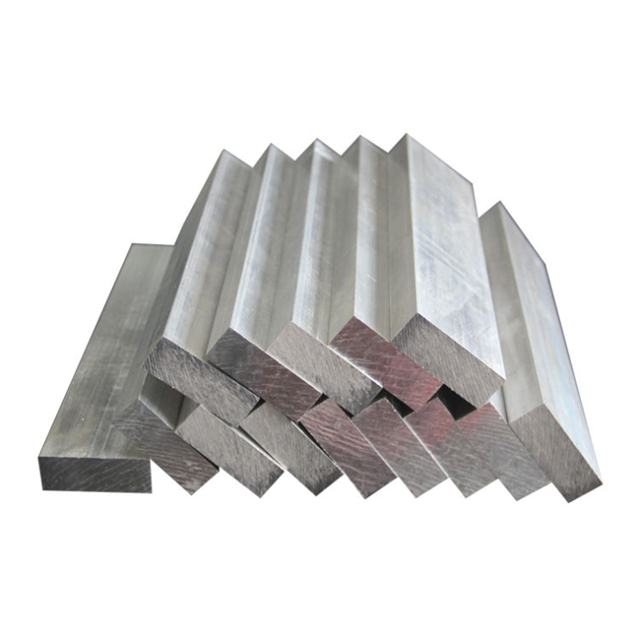

Aluminum

Brass

Copper

Stainless-steel

Steel

ABS

Nylon

POM

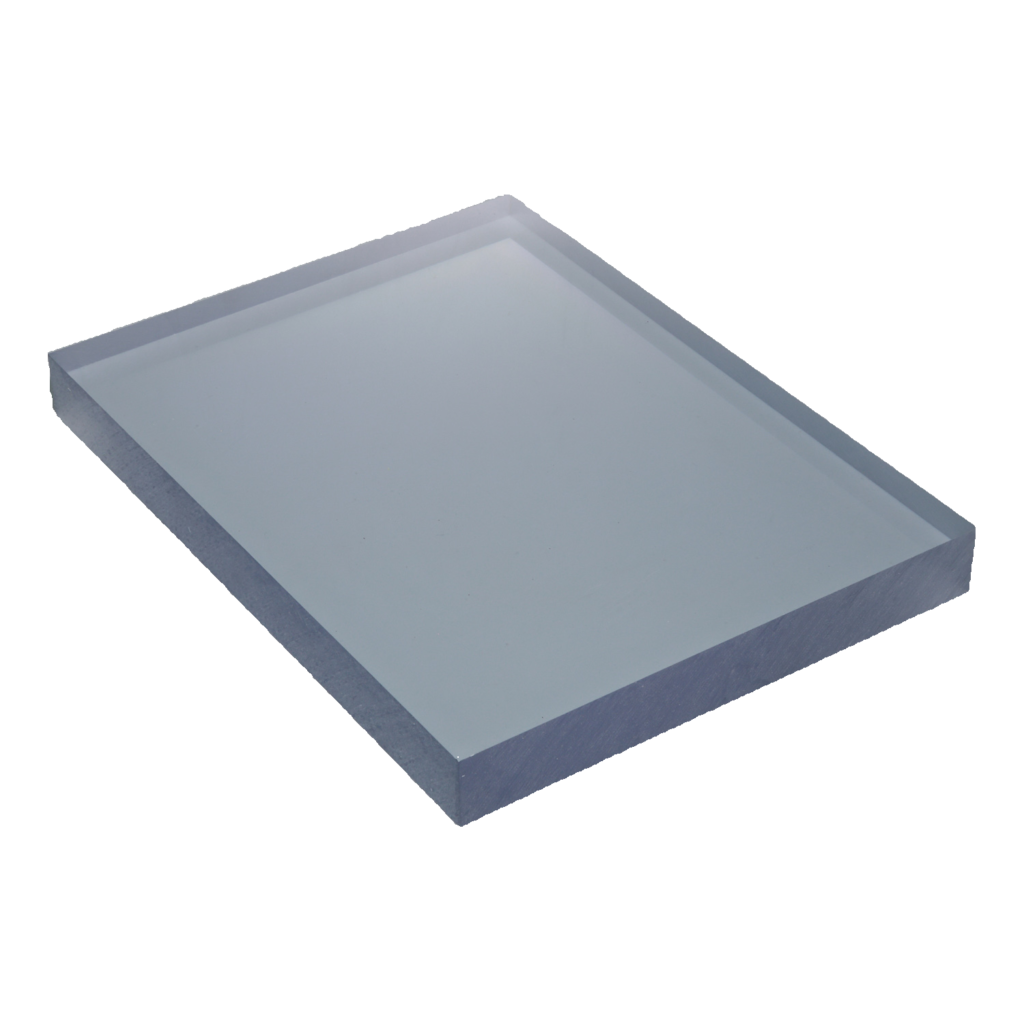

Polycarbonate

PTFE

Surface Finish Options for Turned Parts

Parts that are turned typically have a very smooth surface finish. The as-machined surface finish of the cylindrical areas will typically be much smoother using the lathe than the mill, so consider this when selecting the machining method for those parts that qualify for either method. Areas cut with live tooling, such as flats and slots, may have visible tools marks.

If desired, the metal parts can be lightly bead blasted leaving a fine matte finish. Hard metals like steel and stainless steel can also have edges broken (deburred) with a light bead blast to remove metal slivers, and sharp or rough areas.

Material: Aluminum

Surface Finish: Broken Edge

Material: Aluminum

Surface Finish: Bead Blast

Material: Aluminum

Surface Finish: Sharp Edge