CNC Machining Service for Custom Parts

What is CNC Machining and How Does it Work?

CNC machining is an automated manufacturing process that transforms a solid block or rod of material into a part using end mills. The end mills are controlled by software (G-code) which references a 3D CAD model to reduce the stock material into a desired geometry. Parts can be manufactured relatively quickly due to the level of automation.

There are many types of CNC machines, which include CNC milling and CNC turning. CNC machining is a suitable manufacturing process for one-off prototypes or custom components as well as mid-volume production quantities.

Advantages of CNC Machining

The subtractive process of CNC machining provides multiple benefits for both prototyping and production parts.

- Precision and repeatability

- Tight tolerances

- Production-grade materials

- Quick-turn parts within 1 day

- Lower piece-part price at higher quantities

- Robust post-processing to improve cosmetics and material properties

CNC Machining Applications

CNC machining is widely used throughout the aerospace, medical, automotive industries for its ability to rapidly manufacture precise parts in production-grade materials. Typical CNC parts, include:

- Housings and enclosures

- Brackets

- Fixtures for manufacturing

- Gears and bearings

- Internal mechanical components

- Medical instrumentation

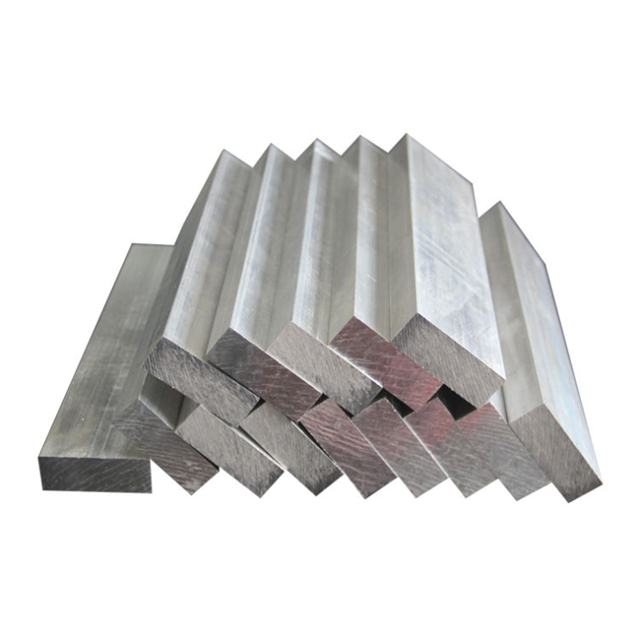

Acceptable Materials for CNC Machining

We work with a wide range of plastic and metal alloy materials, including magnesium, mild and stainless steel, aluminum, brass, and titanium, as well as rigid engineering-grade plastic resins. These materials are part of our standard inventory and can be sourced immediately from reliable, thoroughly vetted, and approved vendors. Additionally, we can provide specialty materials such as super-hard alloys—simply consult with our engineers to learn how we can meet your needs.

Most importantly, to ensure your CNC machined parts meet all regulatory requirements, we have an incoming materials inspection lab equipped with sophisticated analytic testing instruments, including Raman spectroscopy, to confirm the exact chemical and physical properties of all raw materials.

Aluminum

Brass

Copper

Stainless-steel

Steel

ABS

Nylon

POM

Polycarbonate

PTFE

Application

The shapes that can be made by CNC Milling include various flat surfaces, tapers, contours, fillet and radius contours, and threaded surfaces. Although many turned parts use a single axis of rotation, there can also be multiple axes to provide greater flexibility (for example, camshafts).

—Automotive industry:

engine, housing, screws, motor shafts, bearing sleeves, knobs, gaskets, shift levers, hydraulic valves, valve housings, sensor housings

—Machinery industry:

fasteners, bushings, screws (rivets, bolts, nuts), shafts, engine components

—Medical and biotechnology:

medical speculums, auxiliary surgical instruments, optoelectronic instrument components

—Electronic products:

PCB auxiliary board, light-receiving end interface ferrule assembly, optical device metal assembly, product metal shell

Surface Finish and Post-Processing Options

Protolabs offers a variety of CNC machining surface finishing options to meet your part requirements. More advanced coating and plating options are also available.

Surface Finish Options:

- Edges broken with tool marks visible

- Edges broken with light bead blasting

- Sharp edges (tool marks visible)

Coating and Plating Options:

- Anodizing

- Chromate coating

- Powder coating